|

Alaska Survey Associates L.L.C. P.O. Box 772423 Eagle River (Anchorage), Alaska, 99577 Call: 907-360-2145 or 907-280-8771 Fax 907-726-0510 - Email: survey@alaskasurvey.net |

Michael Terminel SAMS® AMS® Principal Marine Surveyor United States Coast Guard Unlimited Master |

| Over 35 years in the Maritime Industry Serving the Pacific Northwest including Hawaii and Guam Will travel Domestic and Internationally | ||

| Colton Terminel Marine Surveyor U.A.A. School of Engineering, Student |

Hunter Terminel Marine Surveyor Alaska Army National Guard "Deployed" |

Demi Shaffer Marine Surveyor USCG Licensed Master |

||

There should be a limited amount of NDT (Nondestructive Testing) in your Survey.

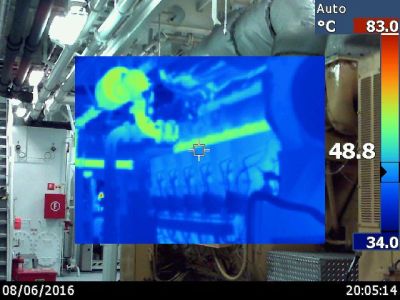

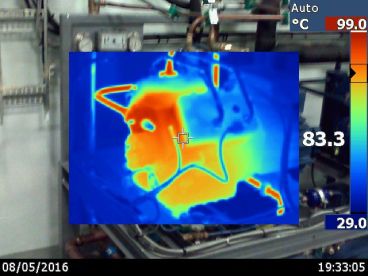

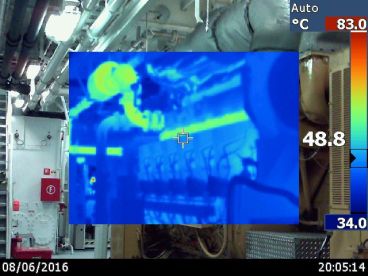

There should be a limited amount of NDT (Nondestructive Testing) in your Survey.If your surveyor is not doing or even offering the tests listed below, ASK WHY NOT, all boats are different, and all boats don"t require the same test to find problems. However, your surveyor needs to be equipped with ALL the proper tools and calibrated instruments to do a job that produce quality quantified results. The report that you receive needs these results. That"s what you"re paying for. Moisture Testing Early warning of osmosis before visible blistering can save your vessel. This test will help identify and trace deck and bulkhead leaks and can give you an early detection device to mitigate costly repairs. FLIR Thermography or thermal imaging is the use of a thermal imaging system to detect, display, and record thermal patterns and temperatures across the surface of an object, this will help detect, electrical hot spots, a cold cylinder, delaminating decks and more. Material Hardness Tester Testing soft metals such as aluminum and its alloys, brass, copper, and some of the harder plastics and fiberglass. Approximate range 25 to 150 Brinnell. This tool is used to identify if materials are breaking down by age, rust, corrosion or dry rot. Ultrasonic Testing If you have an aluminum or steel skinned vessel this test should be done. Ultrasonic testing measures the thickness of the hull by measuring the time sound travels from the transducer through the material to the back end of a part, and then measures the time of reflection back to the transducer. The gage then calculates the thickness based on the velocity of sound through the material being tested. If the vessel your thinking of buying has been beached, has had a section cut out and replaced because of a collision or has a lot of rust or surface corrosion, this will help determine what the current thickness is compared to when it was new. This test is commonly done on aluminum and steel hulled vessels. |

|

|

|

|

|

Copyright © 2016-2020 Alaska Survey Associates L.L.C., Eagle River (Anchorage), Alaska, USA, survey@alaskasurvey.net Installed August 1, 2016, Last Revised July 1, 2020 - Hosted and maintained by Don Robertson |